Combi Boiler Keeps Losing Pressure? So you would like to know How to Fix a Boiler that Keeps Losing Pressure? This is a question often asked of us by Shropshire, Shrewsbury, and, Telford & Wrekin, residents.

Hold tight. If you have actually been fortunate enough to come across this video due to the fact that you have in fact, got an issue with the pressure in your boiler and the reality the pressure is continuously dropping, then fortunately for you we will explain how to cure you combi boiler pressure loss problem.

Indications of a Combi Boiler Pressure Problem

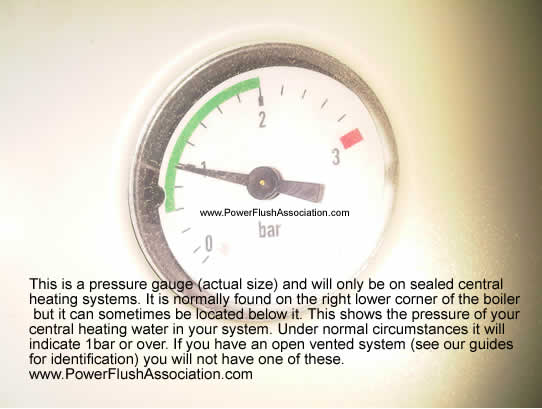

So you’ve been discovering recently that the pressure gauge on the front of your boiler actually keeps loosing pressure until the system cuts-out, and then you have no heating and a cold home, until you re-pressurize the system.

Now if it goes anywhere listed below type of half a bar, then you understand that you’ve got an issue, and undoubtedly if it’s continuously decreasing all the time, you have a faulty central heating system or that regularly you’re topping it up utilizing a filling loop like the one that we’ve started behind us at the minute, then you’ll understand that you’ve absolutely got an issue.

Triggers that May Cause a Combi Boiler to Keep Losing Pressure

Now there’s a couple of things that can trigger this and we’re simply going to go through them, plus offer you a few ideas about how you can perhaps repair the issue. I’ve seen a couple of other videos on YouTube about this and I do not truly seem like they’re covering the problems that can cause a combi boiler to keep losing pressure, extremely well. So we’re going to attempt and do that now for you and I hope you take pleasure in this video.

So let’s go. You might understand that we’ve currently done videos on how pressurized heating units work, and it’s that vital you understand the essentials of how they work. You will need to know it before you will understand the issue with combi boiler pressure drops.

The main points to think of are that when cold water is warmed up inside a boiler and inside a heating unit, the cold water atoms and particles begin to move and get really, really fired up and since of that, they push out into a larger space. To appreciate how this works read the next section:

Comparing Unpressurized Boiler Systems with Pressurized Combi Boiler Systems

On an unpressurized system, you have a tank in the loft with a boiler pressure release pipeline. As the water and gas in the boiler expand in the unpressurized system, that increases the water to in the loft tank, without there being an issue. On a pressurized system, rather of having a water expansion pipeline, you have exactly what’s called an expansion vessel.

How they work is really easy to understand. As it is extremely tough to compress water, combi boilers have a growth vessel with a rubber diaphragm. On one side of the diaphragm you have actually compressed air that’s normally compressed to one or one and a half bar and on the other side you have your heater water.

As the water in the boiler warms up it grows in size (expands), but the pressure is alleviated because the water can expand into the easily compressed air, behind the diaphragm. It does this without letting air into the boiler.

-

Check that the Combi Boiler is Well Filled with Water at all Times and the Pressure Within the Correct Operating Range

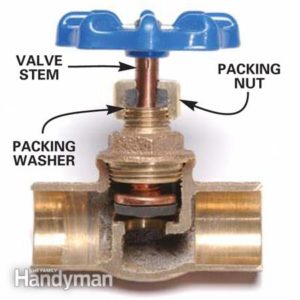

So, for this to work correctly it is necessary to ensure that your combi boiler is good and filled with water at all times. You have a filling loop that fills the cold water from the cold water primary system. So, make certain that this is connected and working correctly. It’s worth keeping in mind, however, that the filling loop water valve which connects to the mains water supply is not open all the time. That valve is normally kept shut, and is only opened occasionally, when needed to raise the pressure on the boiler pressure dial. Once the pressure is withing the correct range it is immediately closed as soon as the pressure has risen to satisfy the pressure requirement indicated by the combi boiler manufacturer.

When you filled the system, and done anything, it is best to shut off both the valves at each side, and get rid of the filling loop intertwined hose pipe and simply hang that behind the boiler somewhere convenient.

The primary factor to be clear about is, since if you’ve got an issue with among the valves, you might be pressurising the heating unit. In fact, you should check that the system is pressurised in the pressure range marked as suitable for boiler function on the pressure dial, or noted in the boiler manufacturers manual.

2. Check for Leakage in your Combi Boiler Heating Unit or Radiator System

So now you’ve got a fundamental concept about how a pressurised heater works. Let’s take a look at issue primary that might trigger a pressure drop. First of all and most undoubtedly of all, you might have a leakage on your heating unit someplace. When it pertains to discovering leakages, the very best thing to do is pop around all the radiator valves for a start and simply make certain there’s no leakages on them. Ensure you raise the heads also to make sure that there’s no weep on top of the valves. Ensure that the compression fittings on each side of the radiator valves are good and tight and there’s no water anywhere.

Simply walk around, feel for water/ dampness with your hands, and make certain that you’ve got no leakages there at all.

That’s top on the list. Attempt to stop any leakages found.

3. Check for Slow Leaks Around the Home

If you conclude that you cannot discover any leakages anywhere, constantly watch out for sort of dark brown spots on the ceiling. They can show leakages. After that, you’re into the gnarly world of bring up floorboards and taking a look under the flooring. Things like that can get quite terrible. So that’s a primary consideration.

4. Check for Combi Boiler Heating Unit Leaks

You may really have a leakage on your heating unit.

A lot of contemporary combi boilers have what are called automated air vents on them. Now they’re fantastic for when it concerns venting a system out. Whatever needs to be vented gets vented instantly and it works remarkably well most of the time.

5. Check for Combi Boiler Corrosion and Resulting Gas Venting Effects

However these venting valves can trigger issues if the heating unit hasn’t got a sufficient quantity of inhibitor in it, or if the pump setting is set too high for the speed. Let’s go through both of those rapidly now. What an inhibitor does is stops the water from corroding with the within the radiators and within the elements of the heater itself.

If there is no inhibitor therein, you’ve got regular water within the radiators, and you are risking terrible things to occur.

Months ago I explored two problem heating systems, similar to this.

One with inhibitor in it, and one with simply water in it. To show you how the corrosion causes problems I popped about 10 nails into each. If you look I believe you can see the distinction between corroded and non-corroded rads. If I simply pop these down so you can have a more detailed take a look at them, you can see the various state in the nails. So, if inhibitor is not within your radiators, that’s precisely what’s going to occur.

Now, another by-product of this is not simply sludge and rust that walks around and stops a heater from working appropriately, it’s likewise hydrogen and other gases. Exactly what takes place is the hydrogen can work its method around to an automated air vent and the automated air vent’s simply doing it’s task, it’s simply sitting there working as intended. A bit of gas is produced by the effects of corrosion, and it lets it out rather easily, however exactly what takes place then is the pressure falls on your boiler.

So, if a Combi Boiler Keeps Losing Pressure and this is the cause. Simply ensure that you’ve got a great quantity of inhibitor in your heater. Add more inhibitor fluid.

6. Check for Combi Boiler Corrosion and Resulting Gas Venting Effects

The next thing to stress over is the pump speed. Now the issue you have is if the pump speed is set too high, and the water is not escaping the pump fast enough, it can do a thing called cavitation. This is exactly what takes place where the pump impellers themselves split the water and gas up and after that, you once again produce hydrogen. The cure is simply to turn your pump speed down, make certain you’ve got a sufficient circulation around the holder system which must stop that from occurring. Now clearly the hydrogen needs to leave someplace and think exactly what happens, as you now know, it gets vented at that naughty little automated air vent, once again and drops the pressure in the system.

So there are the first things you’d take a look at if you had an issue with a pressure drop on your pressurised combi boiler system.

7. Check for Expansion Vessel Faults

The last 2 things to take a look at and sadly the most typical are issues with the growth vessel as well as issues with your pressure relief valve. Let’s take a look at the expansion vessel initially.

Like we explained previously on, the expansion vessel permits the warm water to have someplace to expand into without pressurising the heating unit anywhere above exactly what is a safe limitation.

Now, if the rubber diaphragm ruptures and let’s face it, it is really a moving part which can wear-out, then water will enter into that, the air will enter the heater and get secured of the automated air vent and generally exactly what you’ll wind up with is a problem of no expansion.

Now, you’ll most likely believe that’s going to make the system pressure increase. That is sort of real, however just for a little while. What’ll occur is the system pressure will increase and up and up and in fact require the pressure relief valve to open.

The method to understand that if you’ve got an issue with your growth vessel is to discover exactly what appears like a bike pump port on the top of it or on the side, press that and sadly you’re most likely going to launch all the air out, however if water begins to come out, then that’s a bad thing, fine, and you’re going to have to replace the expansion vessel with a brand-new one.

If you do not discover there’s any water come out, it may have simply lost its charge through that venting valve and you can get a bike pump and again pressurise it. Then utilize the pressure gauge to make sure that it’s pumped up to one or one and a half bar.

Another thing I ‘d likewise state is a sometimes combi boilers are installed and they only have a expansion vessel that represents the growth in volume of the boiler itself. It is insufficient for the expansion of the radiators.

8. Add an Additional Expansion Vessel

I constantly state it’s a terrific concept if your plumbing technician’s in and he’s putting a brand-new boiler in, ask him to install one more expansion vessel elsewhere on the heating system.

This is normally located in the airing cabinet. That way, you’ll cut in half the threat of there being any issue with the expansion vessel, or the pressure relief valve. That is because you’ve got a lot more available expansion volume by doing that.

Pressure relief valves are extremely easy to fit. All they are is a rubber valve with a particular set spring on the back of the valve. When the water gets up to a specific pressure, the pressure presses on that spring then discards the water at a safe area exterior.

They typically include a little 15 mil copper pipeline that protrudes the back wall of the boiler and normally the outlet discharge into a hedge or something. The result of that is that you can never ever see them running or leaking. Let’s face it, a lot of house owners aren’t going to be searching for a small leak like that anyhow.

So if you’ve got an issue with the growth vessel, the pressure is going to increase a lot and it’s going to begin disposing out the pressure relief valve and after that your pressure drop will occur according to that fault.

9. Pressure Relief Valve Replacement

Now an issue you can particularly get with the pressure relief valve is once again that it is a moving part. That you’ve got a spring on the back of the valve will imply that it is a moving part and it’ll get weaker and weaker in time and ultimately 50% of pressure relief valves will stop working after about 10 years.

What occurs is that they begin to gradually leak out and you’ll ultimately discover the result if you’ve got a leakage on the system.

Naturally though where the pressure relief valve’s piped, this problem may be unseen. This can happen if the water disposed through the hidden pipe deposits this water as only a little drip outside where you’re looking.

So a great idea is to simply pop outdoors, search for that little 15 mil pipeline. Once you have found it, and simply run your finger under that and see if that’s where the leak is.

If it is, then you’ve most likely got an issue with the pressure relief valve and you’ll have to get a plumbing company out to change it.

So there you have it!

Conclusion

I hope this video’s offered you a much better concept about the issues you can have when it concerns your pressurized heating unit, and why you’re getting a pressure drop.

There are a number of factors which may be the cause of this.

Let’s face it, the most typical problem units are the expansion vessel, the pressure relief pipeline, or clearly a pipe leakage somewhere on the radiator system and pipework system throughout the house.

Something I would state, it’s constantly a great idea simply to top of the inhibitor in the heater. If you’re uncertain how to do this ask a plumber to do it for you. In fact it is good policy to ask your plumbing technician to come out regularly, and simply do a great little service check examination on it.

To do this drain the entire heating unit out, fill all of it up once again, pop a few tubs of inhibitor in there and your system should be cured.

I hope you’ve enjoyed this article/ video. We do hope you subscribe. See you later-on everybody.

As found on Youtube